How to Test an Oxygen Sensor (P0420)

(This testing applies to 4-wire Heated Oxygen Sensors only, not wide-band or A/F ratio sensors.)

What are the symptoms of a bad oxygen sensor?

- Check engine light

- Lean running engine

- Rich running engine

- Excessive exhaust smell

- Poor fuel economy

- Catalytic converter failure

Recommended Tools

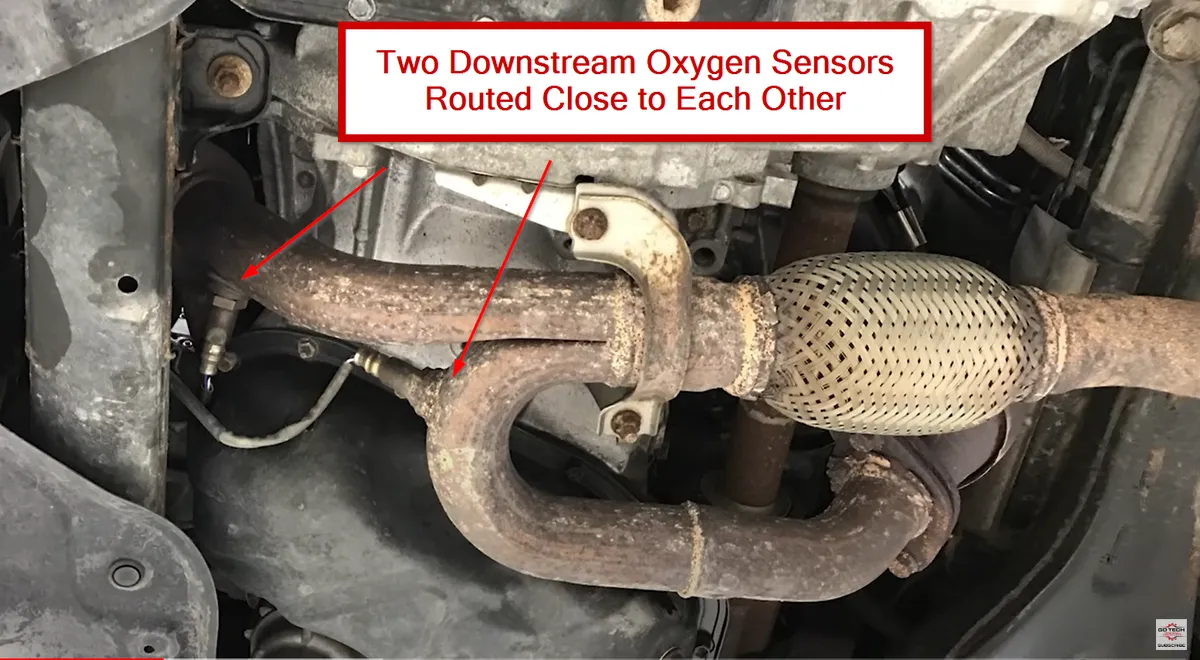

Locate the correct oxygen sensor for testing

- Whether diagnosing a trouble code or testing function, first locate the correct/suspect sensor.

- Determine if it’s Bank 1 (cylinder #1 side) or Bank 2, and whether it’s upstream (before catalytic converter) or downstream (after converter).

- Use the Firing Order Database to confirm the cylinder layout and bank orientation.

Visual inspection

Difficulty: 1/5

Time: ~10 minutes

Tools required: Flashlight, inspection mirror

- Check for damaged wiring, loose connectors, or contact with hot exhaust components.

- Confirm the sensor is securely installed in the exhaust stream.

Test the oxygen sensor heater

Difficulty: 2/5

Time: 30–60 minutes

Tools required: Flashlight, multimeter

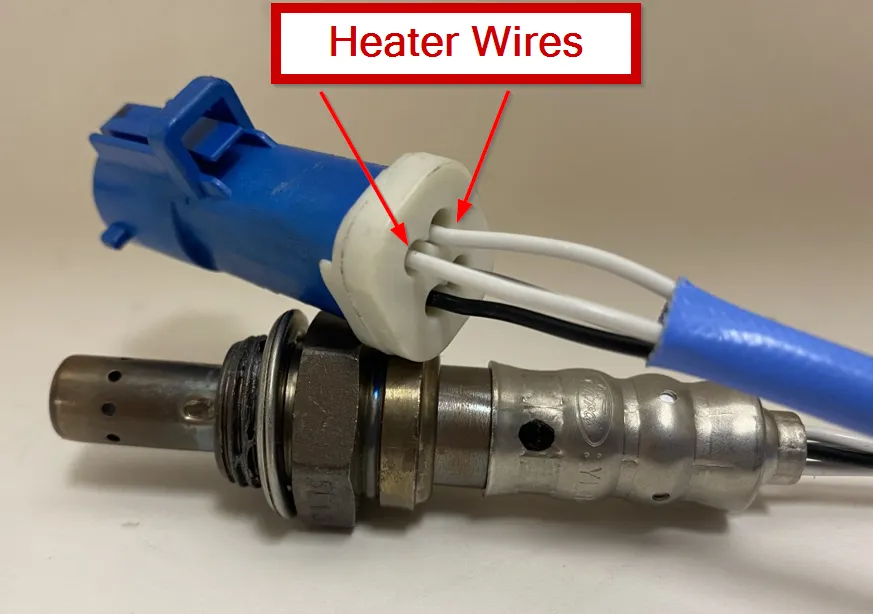

- Identify the two heater wires—on most 4-wire sensors, these are same-colored.

- Using a multimeter set to Ohms, measure resistance between the heater pins.

- Typical range: 4–25 Ω (consult service info).

- If resistance is out of range, replace the O2 sensor.

Suggested Tools:

Check the oxygen sensor signal

Difficulty: 3/5

Time: 30–60 minutes

Tools required: Multimeter or scan tool

- Warm the engine to operating temperature.

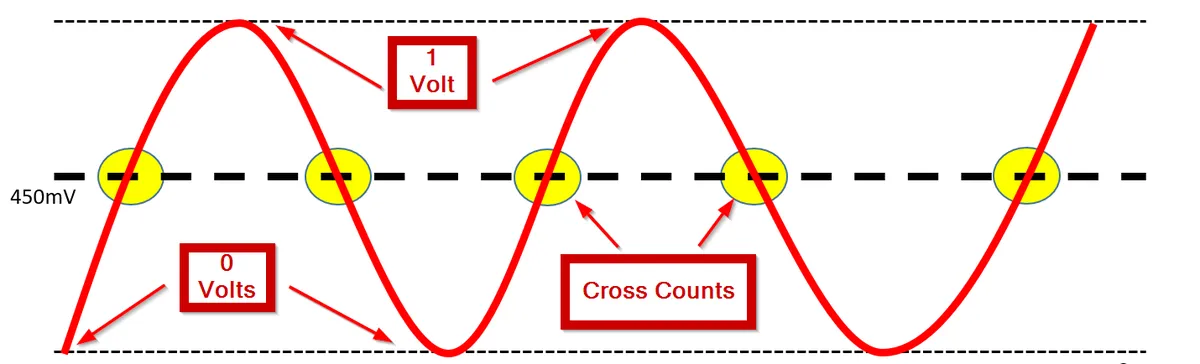

- Monitor O₂ voltage range (0–1.0 V typical).

- Upstream (S1) should switch rapidly above and below 450 mV.

- Downstream (S2) should fluctuate slowly and average between 500–700 mV.

Test the oxygen sensor signal range

Difficulty: 3/5

Time: 30–60 minutes

Tools required: Multimeter or scan tool

- Verify the O₂ sensor can read lean (< 450 mV) and rich (> 450 mV).

- Create a small vacuum leak to induce a lean signal — voltage should drop quickly.

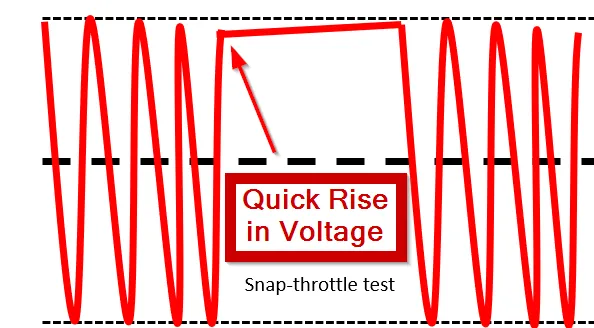

- Perform a snap-throttle to create a rich condition — voltage should spike high.

Helpful Tool:

Live Data Scan Tool

Replace an oxygen sensor

Difficulty: 2/5

Time: 30–60 minutes

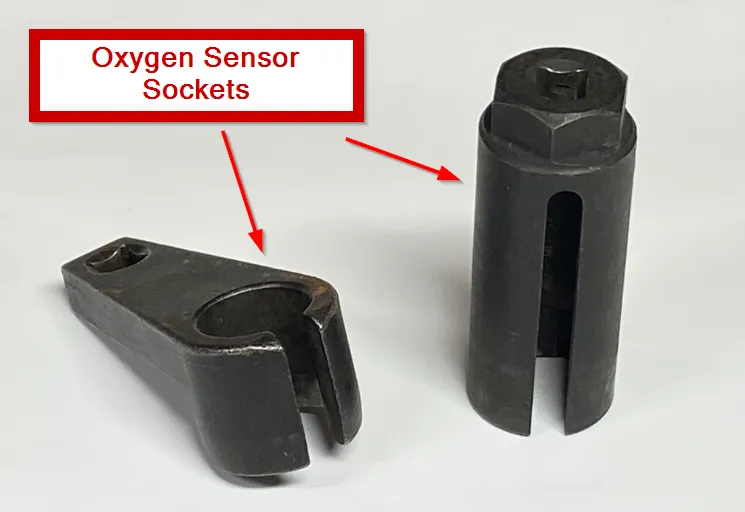

Tools required: O₂ socket or 7/8" wrench

- Disconnect the electrical connector and remove the sensor with an O₂ socket.

- Apply anti-seize if recommended and torque to spec.

- Reconnect harness and clear any stored codes.

Suggested Replacement Sensors:

Oxygen Sensor FAQ

How should an upstream (S1) sensor behave at idle?

It should switch rapidly above and below ~450 mV when the engine is at operating temp.

What’s normal heater resistance?

Typically 4–25 Ω (always verify the exact spec for the vehicle).

Can a bad catalytic converter mimic a bad O₂ sensor?

Yes. A failing cat often makes the downstream sensor switch actively like the upstream sensor.

Upstream vs downstream—what’s the difference?

Upstream (before the cat) reacts quickly to mixture changes; downstream (after the cat) is slower and averages ~500–700 mV during steady cruise.

Is it safe to induce a vacuum leak for testing?

A small, brief leak for testing is fine—watch for a quick drop below 450 mV—then restore the hose immediately.